ABB Robotics is collaborating with UK-based tech start-up Automated Structure, or AUAR, to advance using robotic micro-factories to construct reasonably priced, sustainable low power timber properties.

AUAR’s transformative strategy to integrating robotic automation into the constructing course of will deal with expertise shortages, enhance sustainability, and enhance well being and security by deploying robots in a world community of native micro-factories.

These micro-factories will assemble energy-efficient, reasonably priced buildings from sheet timber. AUAR stories at this time that it has accomplished a £2.6 million seed spherical led by deep-tech and AI fund Miles Forward, alongside ABB Robotics & Automation Ventures and a number of other different traders.

Craig McDonnell, managing director enterprise line industries, ABB Robotics, says: “The growing capabilities of robots enabled by imaginative and prescient and AI, coupled with their inherent pace, flexibility and consistency, makes them the perfect resolution for assembly the rising want for reasonably priced, prime quality, sustainable housing.

“With 95 p.c of constructing corporations in our latest market survey describing sustainability as ‘necessary’ or ‘crucial’ to their companies, and 38 p.c seeing robots as a method of lowering waste, our collaboration with AUAR opens new prospects for homebuilders to ship reasonably priced sustainable properties at scale.”

ABB is already closely concerned in serving to building corporations automate their processes. ABB robots are broadly utilized in a variety of modular meeting and 3D printing constructing tasks worldwide, in addition to tutorial tasks researching new methods to combine robotic automation into building.

The collaboration with AUAR follows the announcement by ABB working with German administration consulting agency, Porsche Consulting, to develop progressive new practices in modular housing manufacture.

AUAR is the brainchild of two architects, Mollie Claypool (CEO) and Gilles Retsin (CTO/chief architect) who’ve labored for over 10 years on robotics, automation, building, and structure. Throughout that point, they’ve relied extensively on help from ABB Robotics to understand their imaginative and prescient.

The connection has already seen ABB Robotics win the prize for ‘Greatest Use of Robotics or Automation in Development’ on the 2023 Robotics & Automation Awards.

AUAR’s automated micro-factory strategy supplies an answer to lots of the challenges going through constructing corporations, together with provide chain points, venture supply and high quality and expertise shortages.

Standard buildings include 1000’s of various parts shipped from all over the world, making it virtually unattainable to automate building. In distinction, AUAR’s aim is to work with one sort of fabric and one sort of machine to dramatically simplify the provision chain.

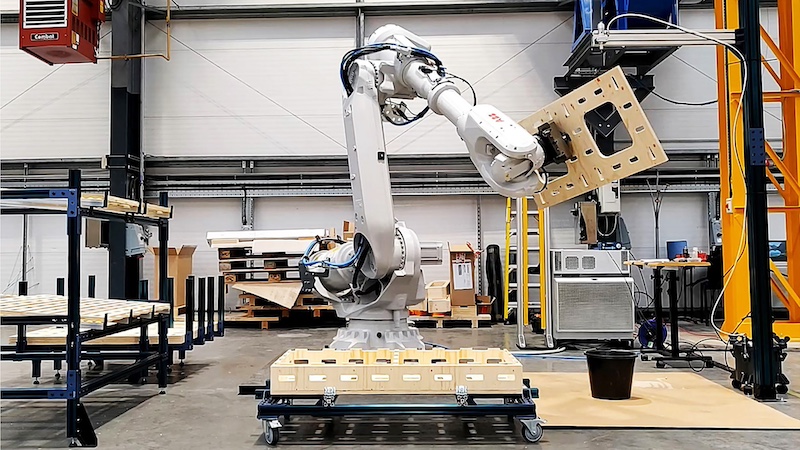

The manufacturing course of makes use of customary sheets of timber. A robotic cuts the sheets into parts and assembles them into models which can be transported to website, enabling full custom-made properties to be inbuilt a matter of weeks.

Whereas lots of the meeting duties are automated, AUAR’s strategy helps native jobs by selling using micro-factories near building websites, the place native contractors and suppliers can coordinate supply.

The micro-factory strategy is versatile sufficient to satisfy no matter every market calls for. Every facility could be scaled to replicate native wants, with the flexibility to ramp up manufacturing by including modular robotic cells.

McDonnell says: “With the deal with the twin wants of constructing extra reasonably priced properties and minimizing the environmental footprint of buildings all through their lifetime, automated modular building presents an amazing alternative to rethink the way in which that the buildings are constructed.

“Our collaborations with AUAR and Porsche Consulting mark an thrilling step in our efforts to speed up using robotic automation within the building business to assist handle its challenges and ship the sustainable buildings of the longer term.”