Editor’s observe: Within the article, Alex Bekker, Head of Information Analytics Division at ScienceSoft, explains how huge information analytics can assist an organization drive income and scale back operational prices. Learn on to learn to begin your huge information journey and be welcome to discover ScienceSoft’s supply in huge information companies to be taught what strategy we comply with to assist our purchasers embrace huge information potential.

As Head of Information Analytics, I take pleasure in finding out the experiences of famend firms who drive nice worth from huge information initiatives, in order that my workforce can supply our prospects comparable and even higher outcomes. Right here, I’ve chosen spectacular huge information use instances from the manufacturing trade, together with, from ScienceSoft’s apply, that I hope will encourage you to embark on an enormous information journey.

#1. Manufacturing optimization

Extracting course of enchancment

A vertically built-in precious-metal producer’s ore grade declined. The one logical technique to keep away from loss was to enhance steel extracting and refining processes. Utilizing sensor information, the producer’s huge information answer recognized what components influenced output probably the most. And the dominant parameter turned out to be oxygen degree. With this perception, the workforce barely modified the leaching course of and elevated the yield by 3.7%. Due to huge information evaluation, the producer now earns $10-20 million moreover yearly. Fairly a achieve, contemplating the ore grade deterioration fee was 20%.

Chemical yield perfection

A number one European chemical compounds producer sought to enhance yield. Utilizing sensors, their huge information answer analyzed how every enter issue influenced manufacturing output. It analyzed temperatures, portions, carbon dioxide move and coolant pressures and in contrast their affect charges to at least one one other. Because of this, they revealed that carbon dioxide move charges massively have an effect on the yield. And by barely altering the parameters, they achieved a big lower in uncooked supplies waste (by 20%) and vitality prices (by 15%), and impressively improved the yield.

Vaccine yield enchancment

An enormous pharmaceutical firm wanted to discover a manner to enhance the yield of their vaccines. To do this, the corporate’s huge information answer analyzed their gear sensor information, revealed interdependencies between numerous manufacturing parameters and in contrast how every of them affected the yield. Then, 9 most important parameters had been recognized, reviewed and adjusted to optimize the manufacturing course of. It improved vaccines’ yield by 50%. Now, the corporate moreover makes $5-10 million a 12 months per one substance.

Sugar-sweet optimization

Excessive humidity ranges and low-quality uncooked supplies badly affected the style of sugar of a giant sugar producer. To combat it, information science got here in use to investigate sensor information and discover correlations between the parameters contributing to the most effective sugar high quality. Happily, with this perception the producer managed to discover a technique to shortly affect product high quality and obtain a unified sugar commonplace no matter exterior components. It allowed them to scale back manufacturing prices, enhance buyer satisfaction and simplify workloads.

#2. High quality assurance

Early-stage car high quality assurance

As early as 2014, BMW used huge information to detect vulnerabilities of their new automobile prototypes. Information was collected from sensors on the examined prototypes and automobiles already in use. On account of huge information evaluation, BMW’s answer (in all probability built-in with their car design and modelling software program) noticed weaknesses and error patterns within the prototypes and in automobiles already in use. It enabled engineers to take away uncovered vulnerabilities earlier than the prototypes truly went into manufacturing and helped scale back remembers of automobiles already in use. Because of this, BMW cannot solely guarantee larger high quality at early levels, but additionally scale back guarantee prices, enhance model repute and possibly save lives.

Jet engine design

Rolls-Royce makes use of huge information extensively. And one among their most attention-grabbing manufacturing huge information experiences is linked with modelling new plane engines. On the design stage, their software program (built-in with an enormous information software) creates simulations of latest jet engines and analyzes terabytes of huge information to see whether or not the brand new fashions are any good. This enables the corporate to search out weaknesses earlier than the mannequin will get to manufacturing, which reduces defect-related prices and helps design the product of a a lot larger high quality. Very sensible, don’t you assume?

#3. Enterprise administration

Information-driven enterprise development

Utilizing huge information analytics in manufacturing, firms can deal with world improvement challenges, comparable to transferring manufacturing to different international locations or opening new factories in new places. Corporations’ historic and exterior information evaluation can set up whether or not it’s nonetheless worthwhile to run factories in present places or at present scopes by constructing predictive fashions and what-if eventualities. In addition to, in the precise palms, huge information can assist discover oceans of unseen alternative, comparable to providing new merchandise and even conquering new markets.

Accessible uncooked supplies

To keep away from prices linked with provide chain failures, an enterprise wanted a greater technique to handle uncooked supplies supply. They determined to make use of their suppliers’ route particulars in addition to climate and visitors information offered by reliable exterior sources to determine the likelihood of supply delays. To do this, their huge information software (fairly presumably built-in with their MRP) used predictive analytics and calculated attainable delays and uncooked supplies shortages. Based mostly on these calculations, the enterprise labored out a supply-related emergency plan and is now in a position to run their manufacturing uninterrupted and keep away from extreme downtime prices.

Predictive upkeep

Intel’s manufacturing unit gear live-streams IoT-generated information into their huge information answer (in all probability built-in with MES). The analytics answer makes use of this information for sample recognition, fault detection and visualization. It permits engineers to see what tendencies require their quick consideration and what actions are wanted to stop severe breakdowns on the store flooring. Such predictive upkeep reduces response time from 4 hours to 30 seconds and cuts prices. In 2017, because of huge information and IoT, Intel predicted saving $100 million. This doesn’t look stunning in any respect: in line with the analysis, predictive upkeep has appeared on firms’ radars precisely in 2017 and has acquired straight to high 3 huge information use instances.

#4. After gross sales

Related automobile automobiles

One in every of ScienceSoft’s prospects from the linked automobile trade makes use of huge information to supply after-sales help to their purchasers and guarantee steady enchancment. The client’s operational facilities analyze in actual time tons of information fed from automobile sensors (diagnostics information, mileage, geolocation, and so on.) and generate insights into the product’s efficiency. The evaluation of this information permits the corporate to watch the product’s state, observe and even predict some malfunctions and supply upkeep service early sufficient to keep away from severe breakdowns. Such strategy permits the shopper to extend the product high quality and improve buyer expertise.

Hull cleansing

As a typical after-sales process, Caterpillar Marine was requested by one if their purchasers to do an evaluation of how hull cleansing impacts fleet efficiency. Caterpillar’s huge information answer (built-in with their Asset Intelligence platform) analyzed information from sensors on ships operating with and with out cleaned hulls. Then, it discovered correlations between the shopper’s hull-cleaning investments and fleet efficiency. Quickly, Caterpillar concluded that their shopper wanted to wash hulls extra usually (each 6.2 months, not 2 years) and that associated investments paid off. As to the producer, huge information allowed them to make sure probably the most environment friendly exploitation of their merchandise and enhance the corporate’s picture.

Wind farm optimization

As a proponent of after-sales with a customized strategy to prospects in manufacturing, Common Electrical helps energy producers use huge information at 4 ranges.

Stage 1. Wind turbine’s sensor information analytics permits energy producers to optimize turbine’s blade pitch and vitality conversion robotically.

Stage 2. Wind farm monitoring software program compares sensor information to predicted values and acknowledges efficiency patterns, which helps energy producers carry out preventive upkeep on the farms.

Stage 3. Energy producers use historic and real-time information to construct predictive fashions, discover correlations, detect faults and acknowledge patterns to optimize the farm’s work.

Stage 4. The information is visualized and offered to high administration for global-scale knowledgeable choice making.

A information on tips on how to begin

If the examples of profitable huge information initiatives triggered your curiosity, I’ll gladly share a roadmap my colleagues at ScienceSoft and I devised for our prospects to set off on an enormous information journey safely and successfully.

Prepared… Set…

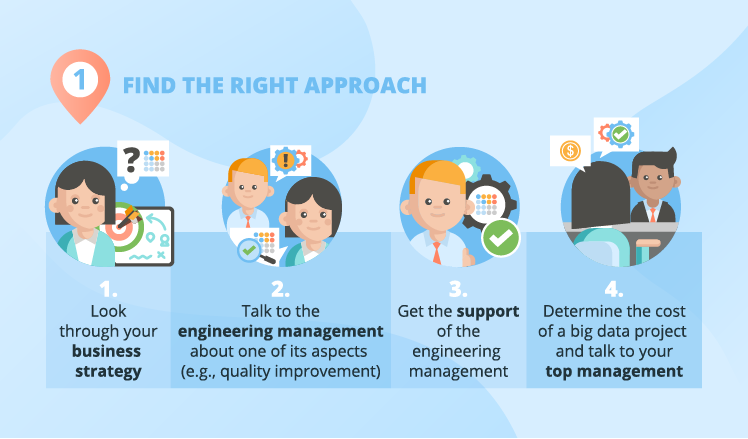

To organize for an enormous information adoption undertaking, the very first thing essential for fulfillment is discovering the precise strategy. Slightly than getting obsessive about the thought of huge information, dashing to get the finances after which failing to extract worth from it, first, it is best to lay the groundwork for the attainable future ‘novelty.’ Let me present you the steps that may assist you obtain business-IT alignment:

Step 1. I all the time advise huge information undertaking sponsors to begin with studying concerning the potentialities of huge information, then have a look at the enterprise technique and outline what targets in it may be achieved with huge information’s assist.

Step 2. It’s best to get extra particulars in your firm’s manufacturing issues and desires. One of the simplest ways to do it’s speaking to the engineering administration at your enterprise and asking them how the standard enchancment course of goes. Likelihood is, the method is problematic and no answer has but been discovered, which is the place you clarify that such challenges may be solved with a factor referred to as huge information analytics.

Step 3. Attempt to get the consent of the engineering administration to show (if wanted) to the corporate’s high administration that they do want huge information. And in addition warn them that their involvement will likely be needed later to assist information analysts perceive the wanted particulars of the manufacturing course of.

Step 4. Decide a sure vary of how a lot a specific huge information undertaking prices and discuss to your high administration about huge information adoption and large information advantages. In our different article, my colleague, Olga Baturina, offered some telling statistics of huge information good points.

In case you want extra particulars on how to make sure enterprise IT-alignment, you may take a look on the information written by my colleague, Boris Shiklo, CTO of ScienceSoft.

Go!

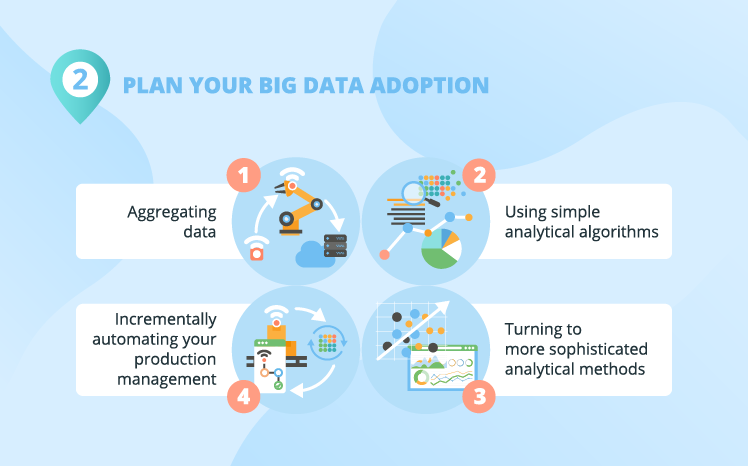

I all the time warn huge information undertaking sponsors towards making use of huge information capabilities to advanced duties proper from the beginning. Identical to you may’t go to house just a few days after deciding to grow to be an astronaut. So, my recommendation to manufacturing firms is to begin out with a easy undertaking (for instance, attempting to attain a steady output high quality at a vaccine manufacturing unit). A easy beginning undertaking means that you can see how huge information can remedy your issues with low dangers and investments. Which, in its flip, is prone to positively have an effect on your high administration’s opinion on huge information and encourage them to plan additional huge information investments (for extra severe analytical tasks).

At ScienceSoft, we often break an enormous information undertaking down into ‘digestible’ phases which are to be approached individually. Listed below are the pattern phases of an enormous information undertaking for manufacturing:

- Aggregating information.

- Utilizing easy analytical algorithms.

- Turning to extra subtle analytical strategies.

- Incrementally automating your manufacturing administration.

Aggregating information

Earlier than any evaluation can occur, it’s a must to begin aggregating information. In some instances, it’s not a downside in any respect: you simply deploy/add sensors in your manufacturing gear, put together information storing amenities and benefit from the move of ‘freshly-cut’ information.

In different instances, comparable to in case your manufacturing cycle is months- and even years-long, it could show tough as a result of you could lack the information on how your manufacturing course of parameters affect output. And with out figuring out it, it’s all actually a shot at the hours of darkness. However don’t get upset: there are methods to combat it. For instance, in ScienceSoft’s tasks, we advocate our prospects to give attention to one a part of their manufacturing course of, reasonably than on the complete course of. That manner they will enhance the general course of by analyzing and adjusting its constituent components.

Making analytical child steps and advancing to huge information strides

At ScienceSoft, we often outline the subsequent levels of revealing huge information insights:

- At first, you may carry out comparatively easy huge information evaluation to make focused modifications in your manufacturing processes (to enhance product high quality, as an example).

- Then, you may dig your information deeper to search out methods to change your small business processes. For instance, you used to carry out reactive upkeep and, with huge information, you begin preventive upkeep.

- When the time comes, you may even remodel your small business mannequin, discovering a greater technique to do it by way of huge information evaluation (say, you resolve to get nearer to the shopper by making the automobiles you produce a wise linked product; you deploy sensors on them, analyze information from automobiles in use and supply after gross sales companies).

The state of affairs, I mostly encounter, is that at early levels, prospects solely want probably the most normal analytical strategies, comparable to correlations and regression evaluation. As their huge information competences and desires develop, analytical strategies grow to be extra elaborate, they usually begin using predictive analytics and machine studying seeking new enterprise alternatives.

Manufacturing administration automation

Automation of your manufacturing administration might be probably the most subtle manner of utilizing huge information in manufacturing processes. The idea of automated manufacturing administration is pretty easy: your historic and incoming sensor information is analyzed in actual time and the management apps ship focused instructions to actuators in your gear.

instance of manufacturing administration automation is the case with Common Electrical’s wind generators. Sensors present information on vitality technology and wind course, in line with which the blade pitch is modified to optimize the wind turbine’s effectivity.

An instance to make it clear

Let me share an instance of a generalized buyer from my apply – an organization who produces child meals and decides to go huge information. They begin with information aggregation (deploy/add information sensors on the manufacturing flooring and put together information storage).

For the sake of the instance, let’s think about that systematically, just a few occasions a month, the newborn meals batches considerably drop in high quality. Now, the large information workforce (along with the engineering workforce, R&D, product management managers) can discover out what causes these high quality drops. And collectively we notice that the manufacturing course of doesn’t permit for the variations within the high quality of uncooked materials (child meals substances). If the substances’ high quality is decrease, the equipment isn’t ‘tuned’ to get a greater high quality output (say, you don’t regulate temperature and cooking occasions). And moreover that, we additionally discover a technique to minimize the manufacturing cycle length. This huge information utility (higher high quality assurance) generally is a good first undertaking.

Getting precious insights shortly and cheaply makes the corporate extra thinking about additional huge information capabilities and extra advanced analytical algorithms. And shortly, the enterprise begins operating predictive analytics, gear wear-out evaluation and machine studying. Amongst different issues, it permits them to carry out predictive upkeep, which permits the employees to react to alarming tendencies on the manufacturing flooring earlier than any actual injury is precipitated.

And because the firm expands globally, we assist the corporate to make use of huge information powers to guarantee and management child meals high quality throughout all of the franchisees.

Now, survive

Sure, whereas beginning big-data-adoption motion, there are all the time impediments. Large information undertaking sponsors I discuss to generally voice the next considerations:

- Missing in-house technical abilities.

I consider, not each enterprise wants full outsourcing. For instance, at early levels, once you’ll must experiment quite a bit, it’s merely simpler, in case your ‘home’ individuals are concerned, thus it’s pure to rent new expert tech staff or retrain previous ones.

- Missing the understanding of huge information potential

In case of outsourcing an enormous information undertaking, your vendor might want to work intently together with your workforce (the engineering workforce, R&D, product management managers, and so on.) to make sure the deep understanding of producing processes. Along with a vendor who has a strong strategy to cooperation, you’ll be capable of see elaborate methods to enhance manufacturing and its administration with huge information potential.

- Resisting the brand new applied sciences.

Some staff – let’s hope the lesser half – will in all probability resist huge information. And there’s nothing private about it: for creatures of behavior, it’s simply extra handy to make use of the previous applied sciences. Coaching your employees in addition to controlling their utilization of the brand new answer can assist cope with this problem.

You at the moment are prepared

The manufacturing use instances present that huge information can convey huge cash and large worth. Additionally they present that huge information is most generally used for manufacturing optimization. And it’s fairly logical: huge information options are actually good at discovering correlations. Whereas manufacturing modifications primarily based on sensibly chosen correlations can enhance yield enormously.

To reap the advantages that huge information affords and begin utilizing huge information in your manufacturing group, you want to fastidiously plan your actions. So, let’s rehearse them. It’s best to:

– Discover the precise strategy to your huge information. Fastidiously analyze your small business wants, discover a technique to fulfill them with huge information.

– Prudently plan your huge information adoption. Don’t soar to probably the most tough half proper off the beginning. Discover a small-scale undertaking to check huge information on. Mixture information, take a look at easy algorithms after which attempt extra daring ones.

– Look ahead to administration challenges. Acquire a radical huge information understanding, don’t rush into outsourcing the undertaking fully and interact a wanted variety of engineering technologists.

However before beginning some actual motion, I counsel you to show to huge information consulting, since it could ease the hardships of huge information tasks and contribute to huge information understanding. If you wish to know extra about our huge information consulting companies, attain out to me.

Large information is one other step to your small business success. We are going to assist you to undertake a sophisticated strategy to huge information to unleash its full potential.